While most companies in the gasification industry are

concentrated on proving the technology and securing commercial contracts,

Rentech, Inc. lept ahead to the next step. Setting its sights on the Holy Grail

of waste to energy, the company focused on creating synthetic transportation

fuel that is clean enough to be used in pipelines and engines.

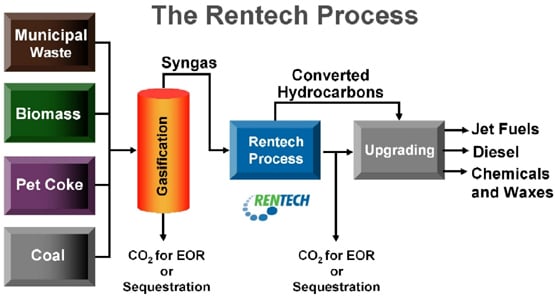

Rentech has developed a patented version of the

Fischer-Tropsch process, utilizing components from smaller companies it has

acquired over several years. Dubbed the Rentech Process, the company uses one

of two gasifiers, a catalyst, reactor and upgrader to convert biomass and waste

materials into ultra-clean synthetic fuel and chemicals.

Although the Rentech Process can work with a variety of

feedstocks, the company is primarily focused on cellulosic materials. After

purchasing SilvaGas, Inc. in 2009, Rentech began offering the Rentech-SilvaGas

gasifier. The patented technology was originally developed in collaboration

with Battelle Labs and the U.S. Dept. of Energy as part of its Biomass Power

Program. A unit ran for several

years in the McNeil Power Station of Burlington, Vt. although web searches

haven’t been able to verify if it is still in operation or owned by Rentech.

Rentech also owns the Rentech-ClearFuels gasifier, which has

a product demonstration unit in Commerce City, Colo. Using a hydrothermal

reformer, the gasifier produces hydrogen in addition to a syngas. According to

transcripts of the company’s quarterly earnings call to investors, Rentech

purchased SilvaGas and its gasifier because it was further down the path to

commercial development than the one it had been developing with ClearFuels.

|

| Courtesy: Rentech, Inc. |

The iron-based catalyst used in the Rentech Process is the

most critical component, according to the company. As the only North

American-based company using it, the iron-based catalyst is mixed with liquid

wax in a slurry bubble column reactor. The syngas is then upgraded to synthetic

diesel fuel (RenDiesel) or jet fuel (RenJet) using UOP’s upgrader. The jet fuel

produced can be blended with conventional jet fuel for use in military and

smaller commercial planes.

While Rentech was initially involved in several projects,

the 2011 fourth-quarter earnings call transcript states that they have altered

their direction and are backtracking a bit. The company has abandoned proposed

projects in Port St. Joe, Fla. and Natchez, Miss. and is trying to find a new

outlet for the rights to the 1.3 million tons of timber it purchased from the

Province of Ontario.

Better BTU Take: While

we applaud Rentech’s initiative, we feel that this is yet another illustration

of a company investing in several projects before having a clear idea of what

is actually involved in developing a project of this magnitude. With the rate

of announced projects exponentially higher than completed projects, each

cancelled project lends credibility to detractors from the renewable energy

industry that say it doesn’t work.

As every company in this industry has had to overcome both

financial and regulatory obstacles, we look forward to seeing where Rentech

goes after regrouping.